If you would like to learn more about the IAEA’s work, sign up for our weekly updates containing our most important news, multimedia and more.

Safety from start to finish

A tour through Jordan’s research reactor facility

Aabha Dixit

Research reactors are often used for more than just research; they are used for education and training, materials testing and producing radioisotopes for medical and industrial applications. Like nuclear power reactors, research reactors must adhere to the highest safety standards during all stages of a project, from design and commissioning to operation and maintenance.

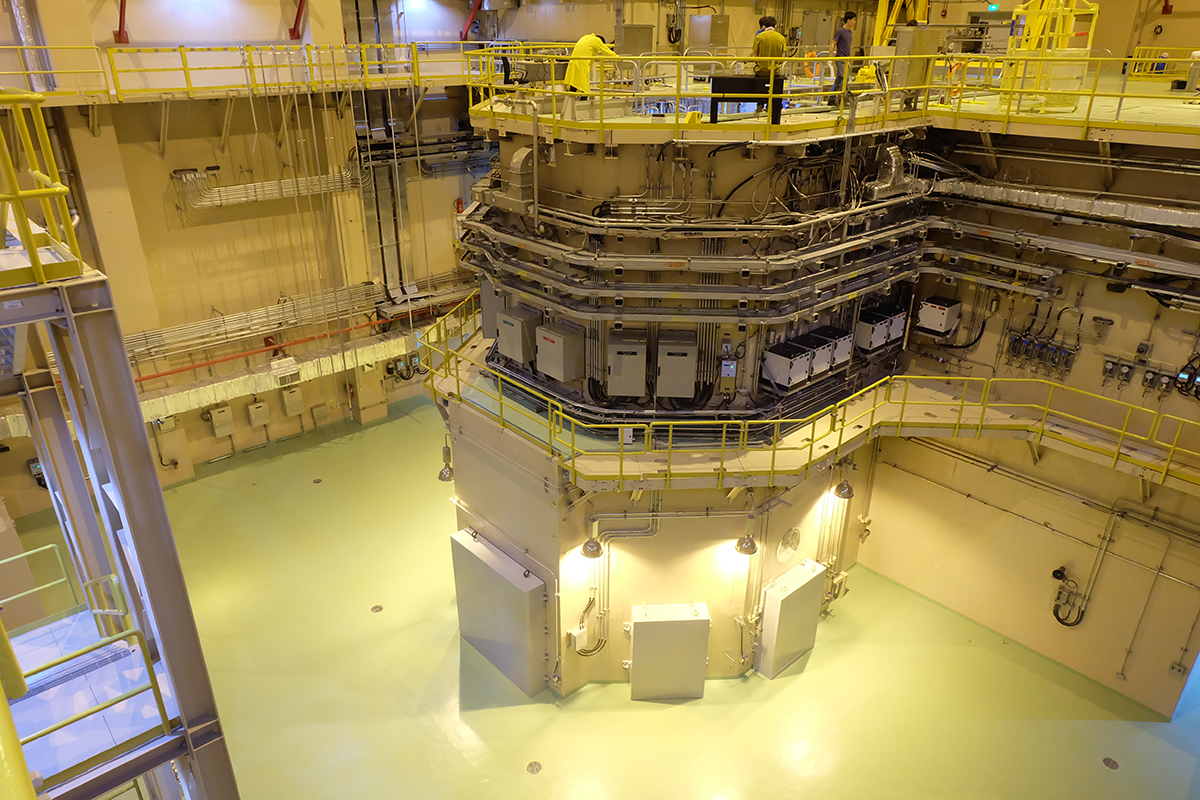

Take a tour through the Jordan Research and Training Reactor (JRTR) project to learn more about research reactor utilization and how safety is implemented every step of the way. The JRTR is a 5 megawatt (MW) reactor and has been designed to be upgradable to 10 MW. This gives Jordan the option of expanding the research reactor’s capabilities in the future.

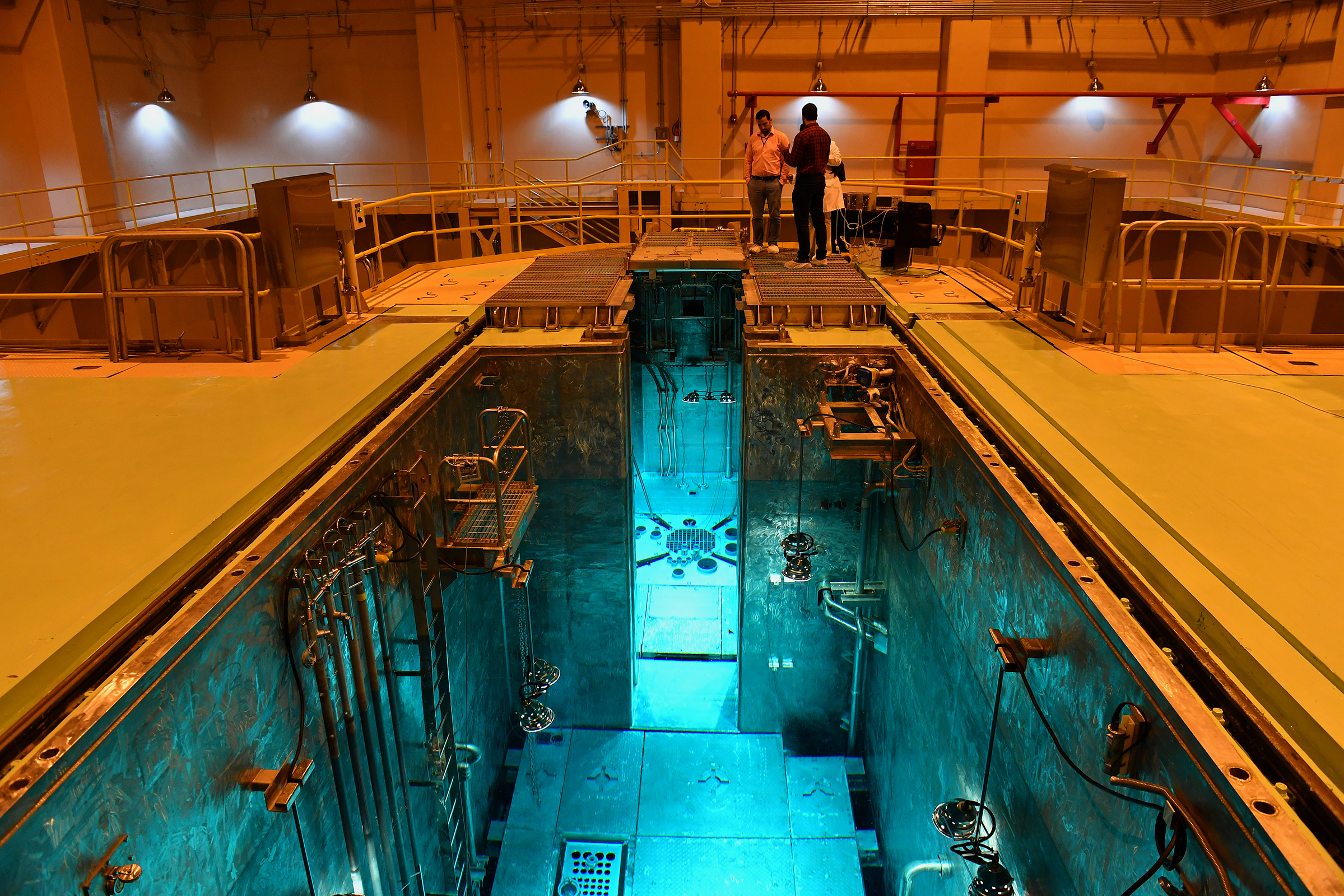

A look inside the JRTR reactor hall.

Following its construction on the campus of the Jordan University of Science and Technology in Irbid, Jordan, the JRTR received its operation license on November 2017.

The JRTR has also received its license from the Jordan Food and Drug Administration to distribute its iodine-131 product line, which consists of various dosages of the isotope in both liquid and capsule form. Iodine-131 is a radioactive isotope of iodine that is often used in radiopharmaceuticals for diagnosing and treating diseases, such as thyroid cancer. The JRTR supplies radiopharmaceuticals to 13 medical centres in Jordan and is continuing to expand its clientele.

Plans are under way to expand the JRTR’s radiopharmaceutical products and to provide other irradiation services, such as the production of silicon, with specifications suitable to the electronics industry.

The JRTR’s neutron beam ports will be used to conduct experiments and the irradiation holes inside the tank will be used to produce radioisotopes for medical and industrial purposes, as well as for other research activities.

The brilliant blue glow in the reactor pool is created by electron particles being released by the fuel and interacting with water. This piercing blue light is known as the Cerenkov effect. As the reactor’s power level increases, the blue glow becomes more intense.

The round openings around the grate are the irradiation holes — located inside the heavy water reflector — that are used for producing radioisotopes, for neutron transmutation doping and for other types of irradiation.

The reactor and service pools contain around 325 545 litres of high purity (demineralized) water. Together, they are 3.7 metres wide and 10 metres deep. The image shows the view through the service pool into the blue reactor pool. It shows the grid on top of the fuel assemblies — a structured group of fuel plates providing fuel to reactors — which is used to store the fuel assemblies in specific arrangements for nuclear safety purposes. The gate that separates the reactor pool from the service pool is also visible.

Water is used to provide a shield against radiation hazards. The water used in such reactors has a high purity level to preserve the physical integrity of the fuel assemblies and prevent the release of radioactive material. The gate between the two pools helps to facilitate operation and maintenance work and makes it easier to handle radioactive components. It is also used to separate the two pools in the event of accidental water drainage.

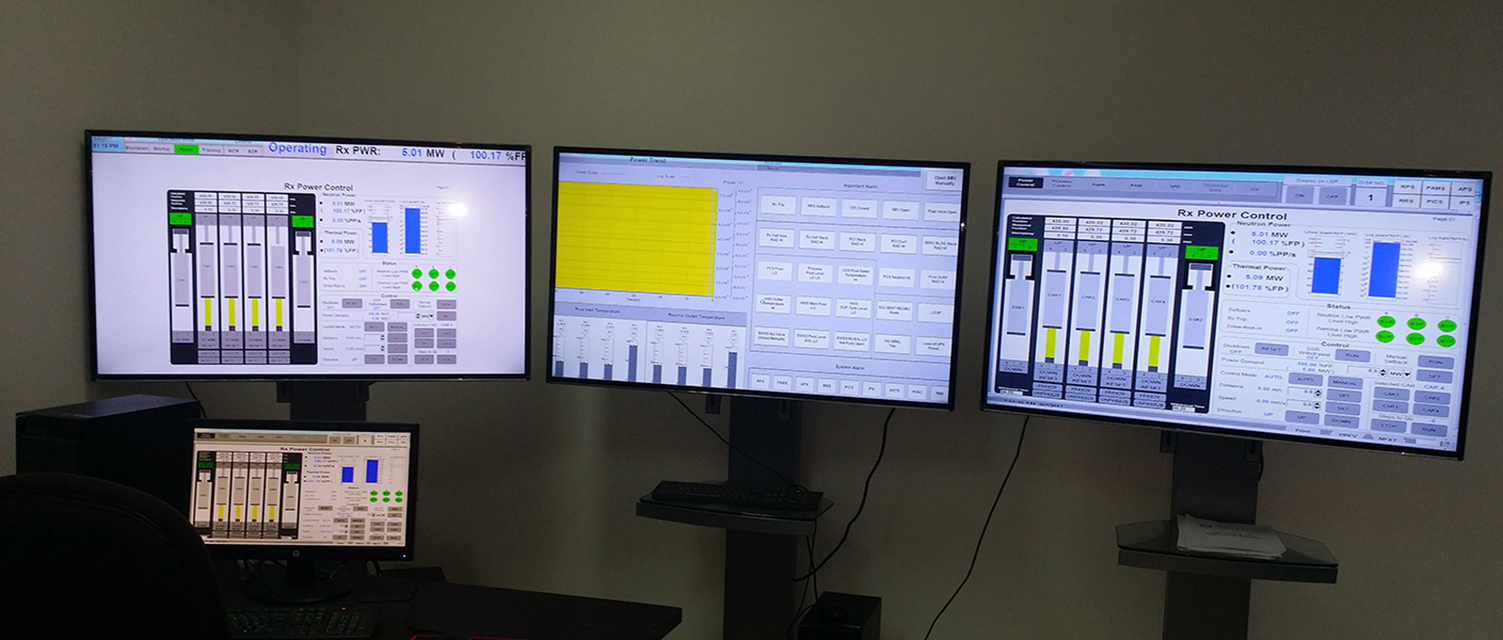

To support the training of JRTR operators and nuclear technology engineers, the JRTR training centre is equipped with a fully functional simulator. These simulators help them to understand and practice the ins and outs of research reactor operation, including possible safety incidents, so that they are well prepared to operate the reactor.

Staff monitoring the JRTR systems from the main control room during the initial operation testing phase.

“Training facilitated by the IAEA for our engineering, scientific and project staff members has been tailored to meet our needs, helping us to prepare our staff and provide them with the knowledge and skills that enabled Jordan to operate this state-of-the-art and versatile facility equipped with advanced safety features,” said Samer D. Kahook, JRTR Manager and Commissioner for Nuclear Research at the Jordan Atomic Energy Commission.

The state-of-the-art JRTR facility also houses three irradiation facilities that are used to support neutron activation analysis, forensic analysis and archaeological research.

‘Hot cell banks’ are another important feature of the JRTR. They allow for the handling of highly radioactive material, such as the material used in the production of radioisotopes for medical and industrial applications. Hot cells are specially designed chambers that shield workers as they use the manipulator arms to work with radioactive materials.

Upon the request of the Jordanian authorities, the JRTR has received IAEA peer review missions, including an Integrated Safety Assessment of Research Reactors (INSARR) mission in December 2016 and a follow-up INSAAR mission in March 2018.

Through such expert missions, the IAEA has also helped to assess the JRTR’s utilization programme for its radioisotope production facility and its neutron activation analysis facility. The IAEA has also assisted the JRTR in conducting peer review and expert missions related to the establishment of integrated management systems.

These missions provide important feedback that helps to refine and strengthen how research reactors, such as the JRTR, are managed, operated and maintained in an effective, reliable and safe manner.

The JRTR facility also has a radioactive waste treatment facility, which received its operating license in March 2019. The facility will handle radioactive waste from the JRTR, as well as from industry and hospitals. After treatment, the radioactive waste will be stored and eventually sent to a final disposal site.