The scores for each section are summed and the results are presented to the user from the NDT Company, including a graphical schema that gives a quick visual overview of how the NDT Company scores with current good practice. Areas that have been identified as being below par could then be addressed by the NDT Company to improve ORP in their respective facility. This is illustrated in figure below or a hypothetical NDT company, which has good standards for the qualifications and training of its radiographers, but has some deficiencies in most other areas of occupational radiation protection practice.

Road Map Tool

A product of ISEMIR-IR Project

Brief Information on the "ROAD MAP" tool for NDT Companies

Background

IAEA- TECDOC- 1747 “The Information System on Occupational Exposure in Medicine, Industry and Research (ISEMIR): Industrial Radiography” was developed under the IAEA’s statutory responsibility to provide for the worldwide application of safety standards for the protection of people against exposure to ionizing radiation. It details the results of the ISEMIR project during 2009–2012 and, in particular, the activities of the Working Group on Industrial Radiography (WGIR). The ISEMIR project arose from the Occupational Radiation Protection International Action Plan, which identified in Action 7 the need to establish networks for the exchange of information on experience and lessons learned between interested parties.

Objectives

As introduced in the TECDOC, a comprehensive worldwide survey on occupational radiation protection in industrial radiography was conducted under the umbrella of the project and the results showed that significant occupational doses do occur, accidents do happen, and the variation in occupational dose per radiographic exposure is considerable. In short, there is a need for considerable improvement in occupational radiation protection, especially in the implementation of optimization of protection.

To this end, the results of the survey were being used by the WGIR to develop a tool so called "ROAD MAP" that aim to help practitioners in the field of industrial radiography. In brief, the road map is a software tool that enables Non-Destructive Testing (NDT) companies to assess and evaluate independently their own performance in the field of radiation protection to meet international safety standards and best practices. Reflecting its heritage in the NDT company questionnaire, the road map is divided into eight separate sections, namely:

Sections

- Qualifications and Training.

- Learning from Incidents.

- Individual Monitoring.

- Workplace Monitoring & Warning Systems.

- Client Interfaces.

- Equipment.

- Internal Control & Inspections.

- Emergency Preparedness & Response.

In each of these sections, there are a series of questions addressing particular aspects of each of these topics. A representative from an NDT company would need to answer the questions in the road map, based on current practice in that company. The response to each question is then scored by comparing it with a measure of good practice. The measure for good practice, for each question, is based either on the relevant third quartile value from the distribution of responses from the survey or on a value given in an international standard. Different weightings are applied to questions, depending on their relative importance, as established by the WGIR through consensus.

How to work with the ROAD MAP tool?

1. Download the free road map tool.

2. Open the Excel file.

3. Fill in your answers in the section "Company answers" in the sheet 1 "Questionnaire".

4. Go to sheet 2 "results" and review your scope and areas to be improved.

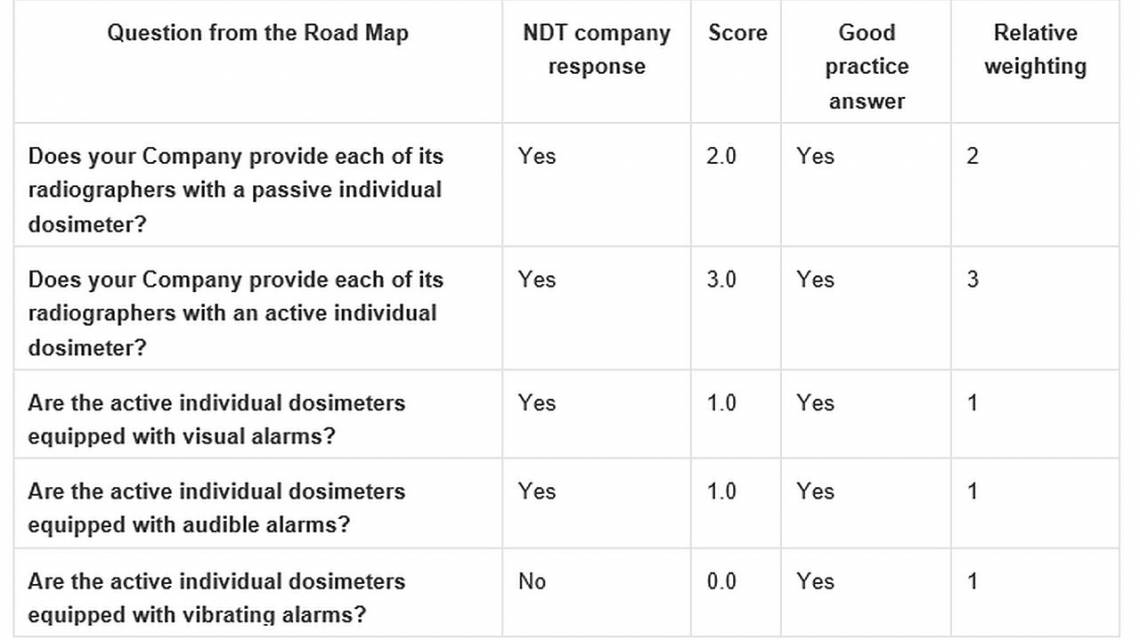

As an example, Table below lists five questions, in the section of the road map on ‘Individual monitoring’ (which can be seen in the sheet 1 - Questionnaire of the Excel file, Road Map), on the dosimeters that are being provided to the industrial radiographers that work for the NDT company, and includes illustrative responses from a hypothetical NDT company.

As can be seen from Table below, the good practice answer to all questions, based on the survey results, is ‘yes’. Further, different weightings are applied to different questions – for example, the provision of an active dosimeter is rated as very important and hence a relative weighting of 3, while the presence of a vibrating alarm is rated less important and assigned a relative weighting of 1.

Table: An example of questions from the road map on the topic of individual monitoring (With illustrative responses from a hypothetical NDT company)