Urea-molasses multinutrient blocks (UMMBs) typically consist of 4–10 % urea, 30–45% molasses and 6–15 % binder. In the 1970s, the blocks were produced mostly by feed manufacturing companies and their use in developing countries was negligible because of the high cost. In the early 1980s, with the realization of the significance of the blocks for smallholders in developing countries, work on simplification of the block production technology gained momentum through the efforts of the Joint FAO/IAEA Centre, Professor R. Leng from the University of New England, Armidale, Australia, and the National Dairy Development Board, Gujarat, India. The Joint FAO/IAEA Centre, FAO and UNDP promoted block technology in many Asian, African and Latin American countries. During the initial phase, up to the mid-1980s, the “hot process” (which required the pre-heating of the molasses and other ingredients) of block production was promoted, despite the high cost of the heating process. In 1986, the FAO Feed Resources Group modified the process to one that did not require heating of the ingredients, and this became known as the “cold process”. The cold process used solidifying agents such as calcium and magnesium oxide, calcium hydroxide, cement or bentonite. This improvement was a real breakthrough, since it allowed the application of the technology at low cost and at small scale, for example at village level by the farmers themselves. In the late 1990s, with the promotion of the cold process through FAO/IAEA Regional Technical Cooperation (TC) Projects RAF/5/041, RAS/5/030 and RAS/5/035 and through IAEA’s national TC projects, the use of block technology picked up in many Asian, African and Latin American countries.

If you would like to learn more about the IAEA’s work, sign up for our weekly updates containing our most important news, multimedia and more.

Technology Transfer: Use of Urea Molasses Multinutrient Blocks in over 50 Countries

Urea molasses multinutrient blocks have been found to be highly beneficial in all member states(MS). The cost:benefit analysis of block use in dairy cattle averaged 1:3.3. It increased dairy farmer income by 5 to 180% per cow per day with an average increase of 38% across the MS. Income from beef cattle and small ruminants increased by up to 30% per animal.

Livestock production in developing countries is largely dependent on fibrous feeds – mainly crop residues and low quality pasture – that are deficient in nitrogen, readily fermentable energy, minerals and vitamins. Protein supplements such as oil cakes are expensive to buy in developing countries, if available at all. This has led to the use of non-protein-nitrogen sources, such as urea, to compensate for the nitrogen deficiency in fibrous feeds. Coupling the use of urea with a source of readily fermentable energy, such as molasses, helps the growth of micro-organism in the rumen, which digest the fibrous feeds. This increases the digestion and consumption of fibrous feeds allowing the animal to maintain, and often increase, productivity.

The use of solid urea-molasses blocks, i.e. solid blocks made with urea, molasses, vitamins and minerals, to supplement the nutrients deficient in the main feed, offers several advantages: ease of transport, storage and use. It has reduced risks of toxicity compared with other approaches, such as giving a small amount of urea in the drinking water, or sprinkling a urea solution on fibrous feeds before they are fed to animals.

These advantages, together with the benefits of enhanced productivity in terms of increased milk and meat production and higher reproductive efficiency in ruminant animal species (include cattle, buffalo, sheep, goats and yak), have led to the adoption of block technology in over 60 countries. Many international organizations, including the Joint FAO/IAEA Centre of the IAEA, FAO, UNDP, ACIAR and SAREC-SIDA, have played important roles in disseminating this technology to such a large number of countries.

The technology

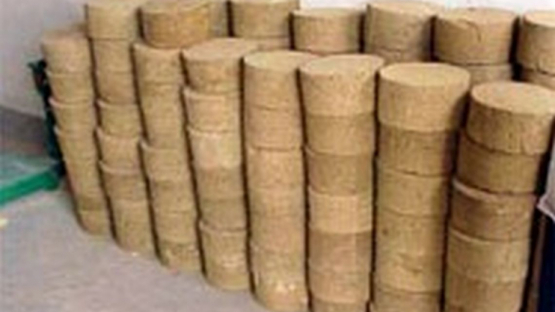

Figure 2. The process of making UMMBs in small scale: mixing, pressing and removal

Block feeding

Figure 3. Cattle licking a UMM block which gives slow release of nutrients

Blocks are made hard enough to ensure that the animal gets a slow release of nutrients through the licking process. Blocks are normally offered to animals in a wooden box or bucket of dimensions slightly larger than that of the block, which restricts biting of the block by animals. The hanging of blocks in front of the animal using a wire passing through the centre of the block has been another approach. Cattle can consume 500 to 800 g/d, sheep and goats 60 to 125 g/d.

The benefits

Below is the summary of the results of IAEA project RAS/5/035 project

- A total of 42 formulations were developed across the 12 Member States (MS) . One to seven formulations were produced per MS, depending on local availability of block components or specific regional nutritional requirements.

- A total of 353 farms and 2592 dairy cattle/buffalo, sheep, beef cattle/heifers and goats were used across the 12 MSs for evaluation of blocks.

- Block consumption a) increased: voluntary feed intake by up to 30%; milk production by 6 to 100%; milk fat by 0.1 to 0.3 percent units; and live-weight by up to 20% for dairy cattle; 30% beef cattle, and 70% for sheep/goats; and b) decreased: time to 1st oestrus by 11 to 30 days in dairy cattle and buffalo; intercalving interval by up to 60 days; and faecal egg count.

- Urea molasses multinutrient blocks have been found to be highly beneficial in all MSs. The cost:benefit analysis of block use in dairy cattle ranged from 1:1.2 to 1:9.3 across MSs, with the average benefit being 1:3.3. It increased dairy farmer income by 5 to 180% per cow per day with an average increase of 38% across the MSs. Income from beef cattle and small ruminants increased by up to 30% per animal.