More than a dozen IAEA Member States are now using ionizing radiation to produce nanoparticles for use in agriculture, medicine, cosmetics and industrial applications, while others are researching ways to create their own products and processes. This specialized field of science and technology was one of the topics discussed at the 2015 IAEA Scientific Forum.

Above, Wanvimol Pasanphan, Assistant Professor at the Centre for Radiation Processing for Polymer Modification and Nanotechnology, Kasetsart University, Thailand, explains the basics of nanoparticles and talks about the exciting possibilities.

How small is a nanoparticle?

Nanoparticles are extremely tiny man-made structures that are measured in nanometres. One nanometre is one billionth of a metre.

In more everyday terms, a nanometre is 100 000 times smaller than the diameter of a single hair. Things in nanoscale can’t be seen with the naked eye. Instead, researchers need to use very powerful microscopes.

Nanoparticles and nanostructures are not entirely new. Rather, it’s humans’ ability to work, measure and manipulate at the nano-scale that is new.

What are nanoparticles used for and how are they made?

Nanoparticles can be used in agriculture, medicine, cosmetics and industry. Due to their nanoscaled size, they are excellent storage, transportation, penetration and distribution devices, carrying and delivering medicines, fertilizers, bioactive compounds, etc. to specific places within an organism or structure.

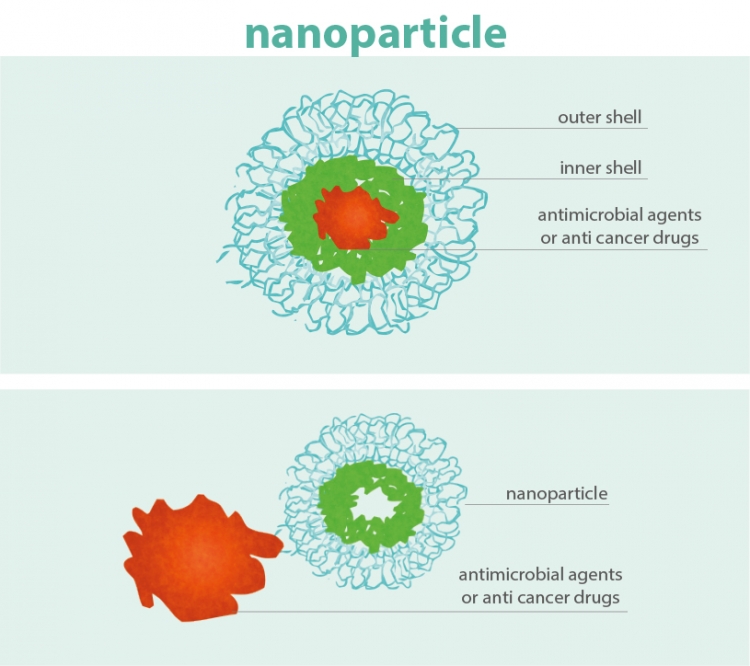

Nanoparticles can be made from inorganic compounds and natural and synthetic polymers. Depending on how the nanoparticle will be used, it can be fabricated into various structures. For example, core-shell polymer nanoparticles are composed of three components: an outer shell (a polymer that provides stability to the chemicals that make up the inner shell); an inner shell (that can be made of water-resistant molecules); and the central core, which contains antimicrobial agents or anticancer drugs (see Figure 1).

Nanoparticles with such a structure may be used for fruit coatings that prevent the growth of fungi, such as Sphaceloma ampelinum, a dark red mould that often appears on grapes.

What are the possible medical applications of this technology?

Nanoparticles can be designed to only release their contents at a certain time (or over a set period of time) and in a certain place. For example, researchers are working on nanoparticles that when coupled to radiopharmaceuticals (or created from radiopharmaceuticals themselves) travel only to cancer cells and nowhere else, and are able to get inside those cells to release the necessary medication.

Twelve Member States — Argentina, Brazil, Egypt, Iran, Italy, Malaysia, Mexico, Pakistan, Singapore, Poland, Thailand and the USA — are involved in an IAEA coordinated research project to use nanoparticles to create targeted drugs for cancer treatment. These nano-pharmaceuticals would be able not only to penetrate cancer cells more easily than other types of pharmaceuticals but also remain within the tumour mass longer than other drugs. If successful, this could revolutionize cancer treatment by decreasing the possibility of healthy cells — and by extension, the patient — being damaged by drugs designed to destroy cancerous cells. These nanoparticles can be structured similarly to what I’ve talked about before or they can look completely different. For example, some researchers are using nanoparticles that look more like the one shown in Figure 2.

Nanoparticles and nanostructures are not entirely new. Rather, it’s humans’ ability to work, measure and manipulate at the nano-scale that is new.