If you would like to learn more about the IAEA’s work, sign up for our weekly updates containing our most important news, multimedia and more.

Nuclear Techniques for the Development of Advanced Materials

Anass Tarhi

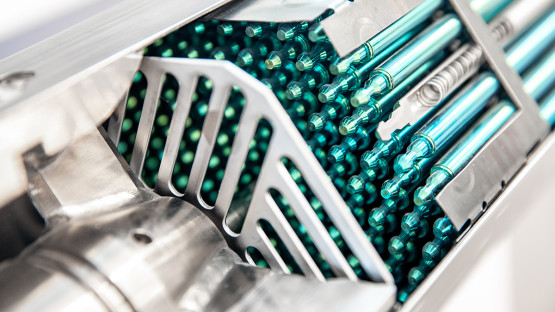

Rod elements used in nuclear reactors are made of advanced materials and must be resilient to heat and radiation. (Photo: Adobe Stock)

From active food packaging based on nanocomposites loaded with essential oils, to radiation-grafted super-absorbent polymers, radiation-processed advanced materials play an increasingly important role in reducing food waste, enhancing agricultural performance, improving health care and much more.

In addition to their light weight and easy fabrication, advanced materials modified using nuclear techniques offer enhanced performance and durability. Radiation technologies, including accelerators, have strengthened their place and, through many applications, contribute to sustainable development.

High-performance materials produced with radiation can be found everywhere and in everything. They are found in everyday objects that have been made stronger and safer. Some of these materials are even used in making your lifestyle more sustainable.

Uses of advanced materials

To create advanced materials or improve the production of high-performance materials, several radiation-assisted processes are now well established and implemented in industry. For example, the increased suitability of plastics or rubbers exposed to radiation enables the production of various materials, such as plastic tubes resistant to heat and pressure used for circulating water and heating fluids in buildings.

“High-performance materials produced with radiation can be found everywhere and in everything,” said Celina Horak, Head of the Radioisotope Products and Radiation Technology Section at the IAEA. “They are found in everyday objects that have been made stronger and safer. Some of these materials are even used in making your lifestyle more sustainable.”

Radiation processing is also applied to dry or harden solvent-free paints, inks and coatings, and to improve the strength, temperature resistance and impermeability of bio-based and biodegradable packaging materials. Porous ceramics with silver nanoparticles generated in situ are now used in various countries for water purification in rural communities.

Benefits of advanced materials in the context of climate change

Meeting growing energy demand while addressing climate change requires further developments in renewable energy production, storage and recycling. “Radiation technologies are well suited to fabricate task-specific membranes and bulk composites for fuel cell technology, to produce more efficiently renewable energy,” said Xavier Coqueret, a professor at the University of Reims Champagne-Ardenne. He said radiation pre-treatment can be used to improve lignocellulosic biomass or the conversion of sunlight energy through advanced photovoltaics.

To address another environmental issue, the global plastic waste burden, Coqueret said efficient recycling methods using radiation are needed in the design of advanced plastic and composite products that would otherwise not be reusable with conventional methods.

Radiation effects on advanced materials

Strong, resilient and durable materials are critical in industry in general but are particularly important in the nuclear sector, where the safety of reactors and the feasibility of fuel cycle operations depend on the materials used. For materials in nuclear reactors, the two biggest challenges are heat — addressed by cooling systems — and radiation.

“Structural materials inside nuclear reactors are subjected to damage from fast neutrons that knock atoms out of position and create hydrogen or helium in the form of gas. This can ultimately lead to swelling, the creation of voids, and various other structural and mechanical changes that limit their ultimate lifetime in service,” said Ian Swainson, a nuclear physicist at the IAEA. “Testing materials against radiation is therefore essential, and accelerators can help make testing more widely available.”

Charged particles lose most of their energy towards the end of their journey through materials, causing significant but localized damage. For this reason, researchers plan to test candidate materials for future nuclear reactors using charged particles from ion beam accelerators.

“Testing materials with an accelerator is faster than using a reactor,” said Swainson, explaining that what can be completed in a day with an accelerator can take a year with a high flux test reactor. Typically, samples do not become radioactive, and damaged areas can be carefully sectioned and examined with microscopic techniques.

In 2016, Swainson helped organize a five-year-long IAEA coordinated research project in which samples of the same material were distributed to multiple accelerator facilities for irradiation, under identical conditions, and the BOR-60 fast research reactor in the Russian Federation for comparison. The post-irradiation analysis will contribute to improving site-to-site reproducibility among accelerator facilities and shed light on how well accelerators screen out poorly performing materials.

In August 2022, the IAEA held its Second International Conference on Applications of Radiation Science and Technology (ICARST-2022) to explore these issues and highlight applications and ionizing radiation developments. The conference, among other topics, focused on advances and current technological or economical limitations in specific areas of advanced materials, and helped review achievements in well-established radiation processes for improved materials performance.